Replacing the shock mounts on a JLO (J.L. click here for more details on the download manual…..

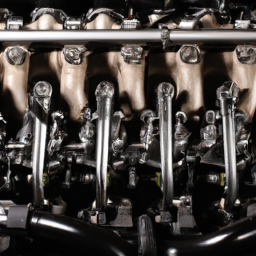

- 1967 JLO L252. rebuilt this engine for the antique snowmobile club raffle sled, a 1967 es-skee-mo

- 1968 JLO 292 Snowmobile Engine – Teardown Pt.1 Today we will be having a go at a vintage, and honestly quite rare, 1968 Arctic Cat snowmobile engine. I found this engine in …

Olson) engine involves a series of steps that can be complex. Here’s a reverse order outline to help you understand the process from completion back to the beginning:

### 6. Reassemble Components

– Reattach any components that were removed earlier, such as the engine cover, exhaust, or any other parts that were disconnected to access the shock mounts.

– Ensure all fasteners are tightened to the manufacturer’s specifications.

### 5. Install New Shock Mounts

– position the new shock mounts in place on the engine.

– Secure them using the appropriate bolts and nuts, ensuring they are tightened correctly.

### 4. Remove old Shock Mounts

– Disconnect the old shock mounts by removing the bolts or fasteners holding them in place.

– Carefully lift the old shock mounts off the engine.

### 3. Access the Shock Mounts

– Depending on the engine’s configuration, you may need to remove surrounding components or covers to gain access to the shock mounts.

– If necessary, lift the engine or use a jack to provide better access.

### 2. Prepare for Replacement

– Gather all necessary tools (sockets, wrenches, etc.) and the replacement shock mounts.

– Ensure the work area is clean and organized.

### 1. Safety Precautions

– Ensure the engine is turned off and cooled down.

– Disconnect the battery to prevent any electrical issues.

This reverse order outlines how to replace the shock mounts on a JLO engine, starting from the completion of the task back to the initial preparation steps. Always refer to the specific engine manual for detailed Instructions and torque specifications.

and torque specifications.

The fuel tank is a critical component of an internal combustion engine vehicle, serving the vital function of storing fuel until it is needed for combustion. Typically constructed from durable materials such as steel or high-density polyethylene (HDPE), the fuel tank is designed to withstand various environmental conditions, including temperature fluctuations and vibrations during driving. Its primary purpose is to hold gasoline or diesel fuel securely, preventing leaks and ensuring safe operation of the vehicle.

Fuel tanks come in various shapes and sizes, tailored to fit different vehicle designs and requirements. They are usually located at the rear of the vehicle, mounted beneath the chassis to optimize space and maintain a low center of gravity. Most fuel tanks are equipped with features such as a filler neck for refueling, a venting system to manage pressure changes, and a fuel gauge that provides the driver with information about the remaining fuel level.

In addition to storage, modern fuel tanks often include various systems to enhance performance and safety. For instance, many tanks incorporate baffles to minimize fuel slosh during cornering or abrupt stops, which helps maintain vehicle stability. Some systems also integrate fuel pumps and filters within or connected to the tank, ensuring that the fuel is delivered efficiently to the engine while minimizing impurities. Overall, the fuel tank is an essential element that not only supports the engine’s operation but also plays a role in the vehicle’s overall safety and performance.