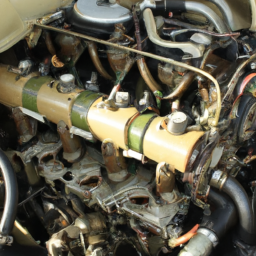

Replacing the fuel pump on a Mitsubishi L2A engine can seem daunting, but with some careful steps, you can do it yourself. click here for more details on the download manual…..

- TRIP REPORT | Cessna 172 Calgary-Springbank to Claresholm (4K) Back at the start of July, I made this 100% serious, entirely unironic, no-fooling-around trip report to document the high-end …

Here’s a simple guide to help you through the process. Make sure to take your time and follow each step carefully.

### Tools and Materials Needed:

– New fuel pump (specific to Mitsubishi L2A)

– wrench set

– Socket set

– Screwdriver set

– Pliers

– Safety glasses

– Rags or towels

– Fuel line disconnect tool (if needed)

– Container for fuel spill (like a small bucket)

### Safety First:

1. **Work in a well-ventilated area**: Fuel fumes can be dangerous, so make sure you’re in a space with good airflow.

2. **Wear safety glasses**: Protect your eyes from any fuel splashes.

3. **Disconnect the battery**: Start by removing the negative terminal from your car battery to avoid any electrical shorts.

### Step-by-Step Guide:

1. **Locate the Fuel Pump**:

– The fuel pump on a Mitsubishi L2A is typically located in the fuel tank or near the engine. Check your user manual or online resources for specific location details.

2. **Access the Fuel Pump**:

– If the fuel pump is in the fuel tank, you may need to remove the tank. To do this, locate the fuel tank straps (metal bands holding the tank in place) and remove them using your socket or wrench.

– Carefully lower the tank while ensuring that no fuel lines remain connected.

3. **Disconnect Fuel Lines**:

– Before removing the pump, you’ll need to disconnect the fuel lines. Use pliers or a fuel line disconnect tool if necessary. Keep a rag handy to catch any spilled fuel.

4. **Remove the Old Fuel Pump**:

– Depending on your setup, you may need to unscrew or unclip the old fuel pump from its housing. Take note of how it’s connected, as you’ll need to replicate this when installing the new pump.

5. **Install the New Fuel Pump**:

– Place the new fuel pump in the same position and orientation as the old one. Secure it with screws or clips as necessary.

6. **Reconnect Fuel Lines**:

– Reconnect the fuel lines to the new pump. Make sure they are secure and free from leaks.

7. **Reinstall the Fuel Tank** (if applicable):

– If you removed the fuel tank, lift it back into place and secure it with the straps you removed earlier.

8. **Reconnect the Battery**:

– Once everything is back in place, reconnect the negative terminal of the battery.

9. **Test the Fuel Pump**:

– Turn the ignition key to the “ON” position (without starting the engine) to allow the fuel pump to prime. Listen for a humming sound, which indicates that the pump is working. Check for any leaks around the connections.

10. **Start the Engine**:

– After ensuring there are no leaks, start the engine. If it runs smoothly, congratulations! You’ve successfully replaced your fuel pump.

### Final Checks:

– Double-check all connections and ensure everything is secure.

and ensure everything is secure.

– Dispose of any fuel-soaked rags and any old parts responsibly.

### Tips:

– Always refer to the user manual for specific details on your vehicle.

– If at any point you feel unsure, don’t hesitate to consult a professional mechanic.

Following these steps should help you replace the fuel pump on your Mitsubishi L2A Engine with confidence!

A battery tray is a crucial component in automotive design, serving as the mounting platform for a vehicle’s battery. typically made from materials like steel, plastic, or composite materials, the tray is engineered to securely hold the battery in place, preventing movement during driving conditions that could lead to damage or electrical issues. The design of the battery tray must accommodate the specific dimensions and weight of the battery it houses, which can vary significantly between different types of vehicles, including conventional internal combustion Engine models and electric vehicles.

One of the primary functions of the battery tray is to provide structural support, ensuring that the battery remains stable and securely fastened, even under vibrations and bumps encountered on the road. Additionally, the tray often features drainage holes to prevent the accumulation of moisture, which can lead to corrosion and negatively impact the battery’s performance and lifespan.

In electric vehicles, the battery tray takes on an even more significant role, as it may be integrated into the vehicle’s chassis for added strength and stability. Some designs allow for easy access to the battery for maintenance or replacement, highlighting the importance of user-friendliness in vehicle design. Overall, the battery tray is a fundamental element that ensures Not only the functionality of the battery but also the overall safety and reliability of the vehicle.