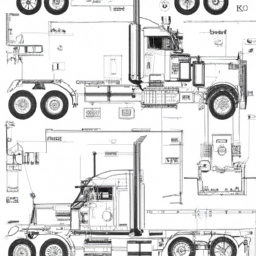

Repairing the Transmission Control Module (TCM) on a Peterbilt 379 involves a number of steps, including understanding the components and systems involved, diagnosing the problem, and performing the repair. click here for more details on the download manual…..

- Peterbilt relay bank location behind dash.

- Peterbilt 379 Transmission Temp Gauge Installation How to Install a Transmission Temperature Gauge DIY.

Below is a detailed guide on how to approach this task, along with a description of each component that may be involved.

### Components Involved in TCM Repair:

1. **Transmission Control Module (TCM)**: The TCM is the brain of the transmission system, controlling the shifting of gears based on various inputs (speed, throttle position, etc.). It processes information from sensors and sends signals to the transmission to ensure proper operation.

2. **Wiring Harness**: This consists of electrical wires that connect the TCM to various sensors, the transmission itself, and the vehicle’s power supply. It is crucial for transmitting signals to and from the TCM.

3. **Sensors**: Various sensors provide input to the TCM, including:

– **Vehicle speed Sensor (VSS)**: Measures the speed of the vehicle.

– **Throttle Position Sensor (TPS)**: Monitors the position of the throttle.

– **Transmission Fluid Temperature Sensor**: Monitors the temperature of the transmission fluid.

4. **Diagnostic Connector**: This is usually located near the driver’s seat and allows for diagnostic tools to connect to the TCM for troubleshooting and data retrieval.

5. **Fuses and Relays**: These protect the electrical components and control the power supply to the TCM and other related systems.

### Steps for TCM Repair:

#### 1. **Diagnosis**:

– **Scan for Codes**: Use an OBD-II scanner or a manufacturer-specific diagnostic tool to check for any error codes related to the TCM. Note the codes as they will guide your troubleshooting.

– **Visual Inspection**: Check the wiring harness for any visible damage, such as frayed wires or corrosion at the connectors. Ensure all connections to the TCM and sensors are secure.

#### 2. **Accessing the TCM**:

– **Location**: The TCM on a Peterbilt 379 is typically located near the transmission or under the dash. Refer to the vehicle’s service manual for the exact location.

– **Removal**: Disconnect the battery to prevent any electrical shorts. Remove any covers or panels that obstruct access to the TCM. Carefully unplug the wiring harness from the TCM.

#### 3. **Inspecting the TCM**:

– **Visual Inspection**: Look for signs of damage, such as burnt components, corrosion, or water ingress. If the TCM is damaged, it may need to be replaced.

– **Testing**: If you have the tools, you can perform tests on the TCM using a multimeter. Check for proper voltage at the power inputs and continuity on the output signals.

#### 4. **Repairing or Replacing the TCM**:

– **Repair**: If you’re experienced with electronics, you may be able to repair minor issues such as broken solder joints or replace damaged components. For most, it is advisable to replace the TCM instead of attempting a repair.

– **Replacement**: If replacement is necessary, obtain a new or refurbished TCM that is compatible with the Peterbilt 379. Install it by reversing the removal steps, ensuring that all connections are secure.

#### 5. **Reconnecting and Testing**:

and Testing**:

– **Reconnect Wiring Harness**: Carefully plug the wiring harness back into the new TCM, ensuring that it is seated properly.

– **Reconnect the Battery**: Reconnect the battery and ensure that all fuses are intact.

– **Clear Codes**: Use the diagnostic tool to clear any existing codes from the TCM.

– **Test Drive**: Take the vehicle for a test drive to ensure that it shifts properly and that there are no lingering issues or error codes.

#### 6. **Final Checks**:

– **Monitor Performance**: After the repair, keep an eye on the transmission performance and check for any new error codes.

– **Check Fluid Levels**: Ensure that the transmission fluid is at the proper level and in good condition.

### Conclusion:

Repairing the TCM on a Peterbilt 379 requires careful diagnosis and an understanding of the vehicle’s electrical systems. It’s important to follow safety protocols and consult the service manual for specific details related to your model. If you’re not comfortable performing the repairs yourself, it is advisable to seek assistance from a qualified mechanic.

The front axle is a crucial component of a vehicle’s suspension and drivetrain system, serving as a structural element that connects the front wheels to the vehicle’s chassis. It plays a vital role in supporting the weight of the vehicle, facilitating steering, and enabling the transfer of power from the engine to the wheels. The front axle can be categorized into two main types: the live axle and the independent axle.

In a live axle setup, both front wheels are connected, allowing them to rotate together, which is common in many trucks and SUVs. This design provides good durability and strength, especially for off-road applications. On the other hand, independent front axles allow each wheel to move independently of the other, enhancing ride comfort and handling. This setup is often found in passenger cars and performance vehicles, as it improves traction and cornering stability.

Front axles also house various components, such as cv joints (constant velocity joints) or U-joints, which allow for the necessary flexibility and movement as the vehicle navigates turns and uneven terrain. Additionally, the front axle supports the braking system, as the brake calipers and discs are typically mounted to it. Overall, the front axle is integral to the vehicle’s functionality, influencing ride quality, stability, and steering response.