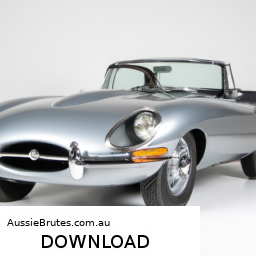

Changing the transmission fluid on a Jaguar E-Type (3.8 or 4.2 liter) can be a rewarding task, but it requires some care. click here for more details on the download manual…..

- 🌊🚤 Don’t you just love the motion of the ocean? Boat size matters when the waves toss you…

- How To Open Any Locked Car Door Without A Key #shorts How To Open Any Locked Car Door Without A Key #shorts.

Here’s a simple guide to help you through the process. Remember, if you feel uncomfortable at any step, it’s always best to consult a professional mechanic.

### Tools and Materials Needed:

1. **Tools:**

– Socket or wrench set

– Screwdriver (flathead and Phillips)

– Funnel

– Oil catch pan

– Rags or paper towels

– Jack and jack stands (or ramps)

2. **Materials:**

– New transmission fluid (check your owner’s manual for the correct type and amount)

– New transmission filter (if applicable)

– New gasket (if applicable)

### Steps to Change transmission Fluid:

1. **Prepare the Vehicle:**

– Park the Jaguar on a level surface.

– Turn off the engine and let it cool down.

– Use a jack to lift the vehicle and secure it with jack stands or use ramps for access underneath.

2. **Locate the transmission Pan:**

– Get under the car and locate the transmission pan. It will be a large metal pan located towards the middle of the vehicle, usually just below the engine.

3. **Drain the Old Fluid:**

– Place the oil catch pan under the transmission pan.

– Using the appropriate socket or wrench, carefully remove the bolts holding the transmission pan in place. Start from one end to let the fluid drain out slowly.

– Be cautious as the fluid may still be warm. Allow all the fluid to drain into the catch pan.

4. **Remove the transmission Filter (if applicable):**

– If your model has a transmission filter, it will be located inside the pan or just above it. Carefully remove any screws or clips holding it in place and take it out.

5. **Clean the transmission Pan:**

– Once drained, clean the inside of the transmission pan with a rag or paper towel to remove any sludge or debris. If a gasket is used, remove the old gasket material from the pan and the transmission.

6. **Install the New Filter (if applicable):**

– If you have a new filter, install it according to the manufacturer’s instructions. Make sure it is seated properly.

7. **Reattach the transmission Pan:**

– Place the new gasket on the transmission pan or apply a gasket sealant if required.

– Carefully position the pan back onto the transmission and secure it with the bolts you removed earlier. Be sure to tighten them evenly to avoid warping the pan.

8. **Add New transmission Fluid:**

– Locate the transmission dipstick tube, which is usually at the back of the engine bay.

– Using a funnel, pour the new transmission fluid into the dipstick tube. Check your owner’s manual for the correct amount of fluid to add.

9. **Check Fluid Level:**

– Start the engine and let it idle for a few minutes. Shift through all the gears to circulate the new fluid.

and let it idle for a few minutes. Shift through all the gears to circulate the new fluid.

– With the engine running, pull the dipstick out, wipe it clean, reinsert it, and pull it out again to check the fluid level. Add more fluid if necessary until it reaches the correct level.

10. **Final Checks:**

– Look for any leaks around the transmission pan.

– Dispose of the old fluid properly at a recycling center or an auto shop that accepts used oil.

### Conclusion:

Congratulations! You’ve successfully changed the transmission fluid in your Jaguar E-Type. Regular fluid changes can help maintain the health of your transmission, ensuring your classic car runs smoothly for years to come. If you have any doubts or encounter issues during the process, don’t hesitate to seek help from a professional. Enjoy your driving!

The fan belt, also known as the serpentine belt or drive belt, is a crucial component in an internal combustion engine’s accessory drive system. This flexible, looped belt is typically made of rubber and is responsible for transferring power from the engine’s crankshaft to various ancillary components, including the alternator, water pump, power steering pump, and air conditioning compressor.

In many modern vehicles, the fan belt is designed as a serpentine belt, which means it has a single continuous loop that winds around multiple pulleys. This design improves efficiency and reduces the number of belts required in the engine compartment, contributing to a more compact and lighter engine layout. The fan belt is essential for maintaining the engine’s operational temperature by driving the water pump, which circulates coolant through the engine and radiator. It also powers the alternator, which generates electricity to recharge the battery and power the vehicle’s electrical systems.

Over time, fan belts can wear out, crack, or become loose due to heat, friction, and environmental factors. Regular inspection and maintenance are vital to ensure the belt remains in good condition, as a failing fan belt can lead to severe engine overheating, loss of power steering, or failure of the electrical system. Therefore, Understanding the function and maintenance of the fan belt is essential for vehicle longevity and performance.