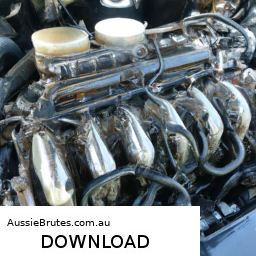

Repairing the gearbox housing on a MACK 12.0L E7 engine involves a series of steps that should be performed in a reverse order to ensure clarity. click here for more details on the download manual…..

- 1997 Mack CH613 semi truck for sale | sold at auction August 15, 2012 SOLD! Ag Equipment Auction This asset was for sale and sold for a contract price of $8800 in an absolute, no-reserve Internet …

- 1990 Mack RB690S for Sale 1990 Mack RB690S Engine Mack E7 12.0l (728 CID) Engine Obviously well maintained. This truck is being sold because we got …

Below is a summarized version of the steps you would typically follow, listed in reverse order:

### 8. Reassemble Components

– **Reattach the Gearbox**: Position the gearbox back onto the engine and align it with the mounting points.

– **Install Fasteners**: Secure the gearbox using the appropriate bolts and torque them to the manufacturer’s specifications.

– **Reconnect Auxiliary Components**: Reconnect any auxiliary components that were removed, such as the starter, oil lines, and electrical connections.

### 7. Refill Fluids

– **Add Transmission Fluid**: Fill the gearbox with the recommended transmission fluid to the correct level.

– **Check for Leaks**: After filling, inspect for any leaks around the housing and connections.

### 6. Inspect and Clean

– **Clean Surfaces**: Ensure all mating surfaces are clean and free of debris or old gasket material.

– **Inspect for Damage**: Check the gearbox housing and other components for signs of wear or damage that might need further attention.

### 5. Remove Gearbox Housing

– **Disconnect Linkages**: Detach any linkages connected to the gearbox, such as shifters or throttle cables.

– **Unbolt the Gearbox Housing**: Carefully unbolt the gearbox housing from the engine. Make sure to keep track of all fasteners.

### 4. Remove the Gearbox

– **Lift the Gearbox**: Using a hoist or suitable lifting device, carefully remove the gearbox from the engine.

– **Support Weights**: Ensure that the gearbox is adequately supported to prevent damage during removal.

### 3. Drain Fluids

– **Drain Gearbox Fluids**: Before starting the disassembly, drain any oil or fluid from the gearbox to prevent spills.

### 2. Prepare Workspace

– **Gather Tools and Equipment**: Ensure you have all necessary tools, including wrenches, sockets, and a torque wrench.

– **Ensure Safety**: Wear appropriate personal protective equipment (PPE) and make sure the engine is cool and secure.

### 1. Disconnect Battery

– **Disconnect Battery Cables**: Always start by disconnecting the battery to prevent any electrical issues during the repair.

### Important Notes:

– **Follow Manufacturer Guidelines**: Always refer to the specific service manual for the MACK E7 engine for detailed instructions and torque specifications.

and torque specifications.

– **Safety First**: Use proper lifting techniques and equipment when handling heavy components.

By following these steps in reverse order, you can effectively repair the gearbox housing on a MACK 12.0L E7 engine while ensuring safety and accuracy in your work.

The brake disc, also known as a brake rotor, is a crucial component of a vehicle’s disc braking system, which is designed to slow down or stop the vehicle when the brake pedal is engaged. Typically made from cast iron or carbon composite materials, brake discs are circular metal plates that are mounted on the wheel hub. Their primary function is to provide a surface for the brake pads to clamp down on, generating the friction necessary to decelerate the vehicle.

When the driver presses the brake pedal, hydraulic pressure is transmitted through the brake system to the brake calipers, which house the brake pads. The calipers then squeeze the brake pads against the brake disc, creating friction. this friction converts the kinetic energy of the moving vehicle into thermal energy, effectively slowing it down.

Brake discs come in various designs, including vented, slotted, and drilled configurations, each offering distinct advantages. Vented discs, for instance, have internal air channels that help dissipate heat more effectively, reducing the risk of brake fade during prolonged use. Slotted and drilled discs enhance performance by improving gas and moisture dissipation, which can lead to better grip and stopping power.

Regular inspection and maintenance of brake discs are essential for vehicle safety, as worn or warped discs can lead to reduced braking efficiency and increased stopping distances. Overall, brake discs play a pivotal role in ensuring a vehicle’s braking system operates effectively, contributing to overall road safety.