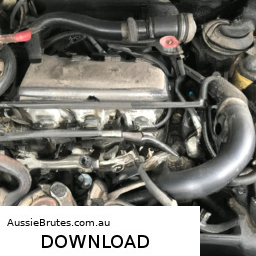

Replacing the clutch release bearing on an Isuzu 4JG2 engine involves several steps. click here for more details on the download manual…..

- ISUZU BIGHORN 1994. VIDEO TEST 4GJ2.

- 4JG2 Isuzu Trooper 3.1 turbo silencer removed

Here’s a detailed breakdown of the tools and process you might need:

### Tools Required:

– **Socket Set**: A comprehensive metric socket set (8mm to 19mm) is essential for loosening and tightening bolts.

– **Torque Wrench**: To ensure that bolts are tightened to the manufacturer’s specifications.

– **Ratchet and Extensions**: For better access to hard-to-reach bolts.

– **Screwdrivers**: Both flat-head and Phillips screwdrivers for prying and removing clips or small components.

– **Pliers**: For removing retaining clips or adjusting wires.

– **Clutch Alignment Tool**: To help align the clutch plate during reassembly.

– **Jack and Jack Stands**: To safely lift the vehicle for better access.

– **Transmission Jack**: For supporting the transmission during removal.

– **Gasket Scraper**: To clean old gasket material from the surfaces.

– **Brake Cleaner**: For cleaning components.

– **Grease**: For lubricating new bearings and components during reassembly.

– **Safety Gear**: Gloves and safety glasses to protect yourself during the process.

### Procedure:

– **Prepare the Vehicle**:

– Park the vehicle on a flat, stable surface.

– Disconnect the battery to prevent any electrical issues.

– Lift the vehicle using a jack and secure it with jack stands for safety.

– **Remove the Transmission**:

– Remove the drive shafts if applicable (you may need to Disconnect the differential or other components).

– Unbolt the transmission from the engine. This usually involves removing bolts from the bell housing.

– Disconnect any wiring harnesses, speedometer cables, and linkages connected to the transmission.

– Use the transmission jack to carefully lower and remove the transmission.

– **Access the Clutch Assembly**:

– Once the transmission is removed, you should see the clutch assembly.

– Remove the bolts securing the pressure plate to the flywheel. keep track of their arrangement for reassembly.

– Gently pull off the pressure plate and clutch disc. Note the orientation for reinstallation.

– **Remove the Old Release Bearing**:

– The release bearing is typically mounted on the clutch fork or a carrier. Carefully slide it off the fork.

– Inspect the fork for wear or damage, as it’s also important to replace or repair if necessary.

– **Install the New Release Bearing**:

– Lubricate the new release bearing lightly with automotive grease, ensuring not to overdo it.

– Slide the new bearing onto the clutch fork or carrier, ensuring it is seated correctly.

– **Reassemble the Clutch Components**:

– Position the clutch disc onto the flywheel, ensuring it’s properly aligned.

– Use the clutch alignment tool to maintain the disc’s position while installing the pressure plate.

– Secure the pressure plate to the flywheel with the bolts you previously removed, tightening them in a crisscross pattern to ensure even pressure.

– **Reinstall the Transmission**:

– Carefully lift the transmission back into place, aligning it with the engine.

– Reconnect all wiring, linkages, and drive shafts that were removed earlier.

– Bolt the transmission back to the engine, ensuring all bolts are tightened to specification using a torque wrench.

– **Final Checks**:

– Reconnect the battery.

– Check the clutch operation by pressing the clutch pedal before starting the vehicle, ensuring it engages and disengages smoothly.

and disengages smoothly.

– Start the engine and test drive the vehicle to confirm proper operation of the clutch.

– **Cleanup**:

– Dispose of any old parts responsibly.

– Clean the workspace and tools to maintain safety and organization.

### Safety Precautions:

– Always wear safety gear, including gloves and glasses.

– Ensure that the vehicle is stable on jack stands before working underneath it.

– Be cautious of hot components and sharp edges.

By following these detailed steps and using the appropriate tools, you can successfully replace the clutch release bearing on an Isuzu 4JG2 engine.

A window motor is an essential component of a vehicle’s power window system, allowing for the automatic raising and lowering of car windows with the simple push of a button. Typically located within the door panel, the window motor is an electric device that drives the window regulator mechanism, which physically moves the window glass up and down.

When the driver or passenger activates the window switch, an electrical current flows to the motor, which then spins a small gear or set of gears, converting electrical energy into mechanical energy. This mechanical energy is used to turn a cable or lever system that is connected to the window regulator. The window regulator can be either a cable-driven or a scissor-type mechanism, both of which have the primary function of guiding the window glass as it moves, ensuring it remains aligned within the window frame.

Window motors can vary in design, with some using a direct current (DC) motor that is specifically engineered for this application. Over time, window motors may experience wear and tear, leading to issues such as slow operation, intermittent movement, or complete failure. Common causes of malfunction include electrical issues, mechanical binding, or damaged components. Regular maintenance and timely repairs can ensure the reliability and longevity of window motors, contributing to overall driving comfort and convenience. In modern vehicles, window motors are often integrated with other electronic systems, enhancing features like one-touch operation and anti-pinch safety mechanisms, which prevent the window from closing on an obstruction.