Sure! click here for more details on the download manual…..

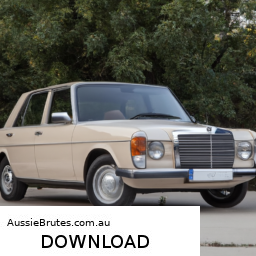

- Bagged Mercedes W114 Feature

- 1971 250 Mercedes w114 starter not engaging Becker radio

Replacing the shift solenoid on a Mercedes W114 or W115 can be done with some basic tools and a little patience. Here’s a step-by-step guide to help you through the process.

### Tools and Materials Needed:

– Socket set (with extensions)

– Screwdriver set

– Pliers

– Replacement shift solenoid

– Torque wrench (optional)

– Clean rags

– Safety glasses

– Gloves (optional)

### Step-by-Step Guide:

#### 1. **Safety First**

– Park your car on a flat surface and turn off the engine.

– Disconnect the battery by removing the negative terminal to prevent any electrical issues.

#### 2. **Locate the Shift Solenoid**

– The shift solenoid is usually located on or near the transmission. In the W114/W115 models, you may find it on the side or rear of the transmission.

– Refer to your owner’s manual or a service manual specific to your vehicle for exact locations.

#### 3. **Access the Transmission**

– Depending on the model, you might need to lift the car using jack stands to get better access to the transmission. Always ensure you’re working safely and securely.

– You may need to remove a few components (like a cover or other parts) to get to the solenoid.

#### 4. **Disconnect the Wiring**

– Carefully disconnect the electrical connector from the solenoid. There might be a clip or tab that you need to press or lift to release it.

#### 5. **Remove the Old Shift Solenoid**

– Use the appropriate socket to remove the bolts or screws securing the solenoid in place. Keep these fasteners, as you will need them to install the new solenoid.

– Gently pull out the old solenoid from its position.

#### 6. **Install the New Shift Solenoid**

– Take your new shift solenoid and carefully insert it where the old one was. Make sure it’s seated properly.

– Reinstall the bolts or screws you removed earlier to secure the solenoid in place. If you have a torque wrench, refer to the specifications for the correct torque setting.

#### 7. **Reconnect the Wiring**

– Plug the electrical connector back into the new solenoid. Make sure it clicks into place securely.

#### 8. **Reassemble Any Removed Components**

– If you had to remove any parts to access the solenoid, make sure to reassemble them. Double-check that all bolts and screws are tightened properly.

#### 9. **Reconnect the Battery**

– Once everything is back in place, reconnect the negative terminal of the battery.

#### 10. **Test the Vehicle**

– Start the Engine and allow it to idle for a moment.

– Shift through the gears to ensure that the new solenoid is functioning correctly. You should notice smoother shifting.

### Final Tips:

– Always consult a repair manual specific to your vehicle for more detailed information and torque specifications.

and torque specifications.

– If you’re uncertain about any part of the process, don’t hesitate to ask for help from someone with more mechanical experience or consult a professional mechanic.

– Dispose of the old solenoid properly.

By following these steps, you should be able to replace the shift solenoid on your Mercedes W114 or W115 successfully! Good luck!

A wheel cylinder is a crucial component of a drum brake system, commonly found in many vehicles, particularly older models and some contemporary designs. It plays a vital role in the braking process by converting hydraulic pressure from the brake master cylinder into mechanical force that actuates the brake shoes against the inner surface of the brake drum.

Typically constructed from cast iron or aluminum, a wheel cylinder consists of a cylindrical housing that contains one or more pistons. When the driver presses the brake pedal, hydraulic fluid from the brake master cylinder is forced through the brake lines into the wheel cylinder. This hydraulic pressure moves the pistons outward, pushing the brake shoes against the brake drum. As the brake shoes make contact with the drum, they create friction, which slows down or stops the rotation of the wheel, thereby bringing the vehicle to a halt.

Wheel cylinders are equipped with rubber seals to prevent hydraulic fluid leaks and ensure reliable operation. Over time, these seals may degrade due to exposure to heat, moisture, and contaminants, leading to leaks that can reduce braking efficiency. Regular inspection and maintenance of the wheel cylinder, including checking for leaks and ensuring proper function, are essential for safe vehicle operation. If a wheel cylinder fails, it can result in uneven braking, increased stopping distances, and potential safety hazards, making timely replacement crucial. In summary, the wheel cylinder is a key player in the hydraulic braking system, ensuring effective and safe vehicle deceleration.